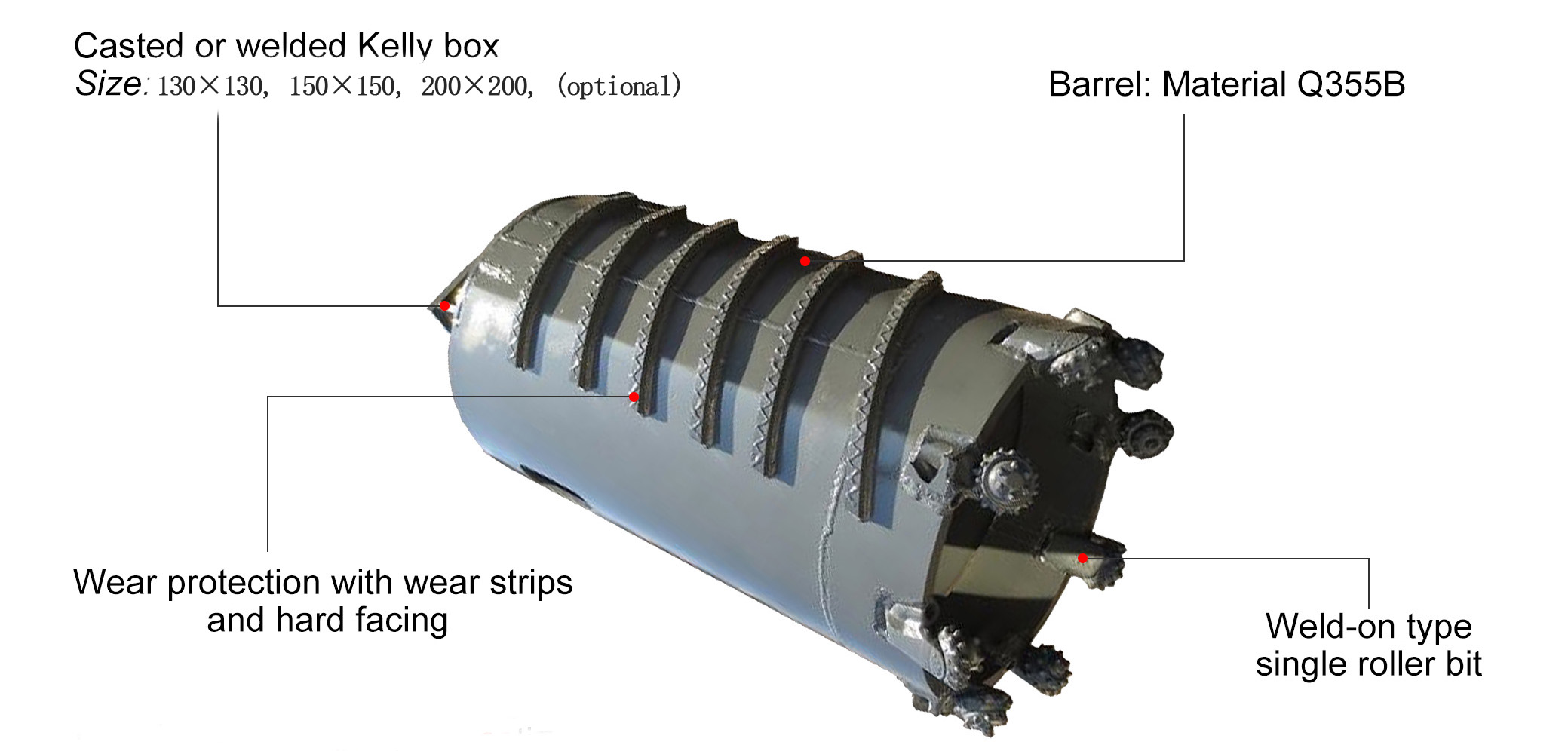

Core Barrel with Roller Bit

Feature:

1. Cutting rings with rock drilling bits and releases the internal stress of rock.

2. Cutting with the method of rolling and squeezing can increase the anti-wear ability of the barrel.

3. Small barrel facilitates the coring operation, large barrel performs stage breaking.

4. The barrel design incorporates spiral wear-resistant strips to prevent abrasion and extend the lifespan of the barrel

5. Suit with the medium or slightly weathered rock, hard or superhard bedrock.

Advantages:

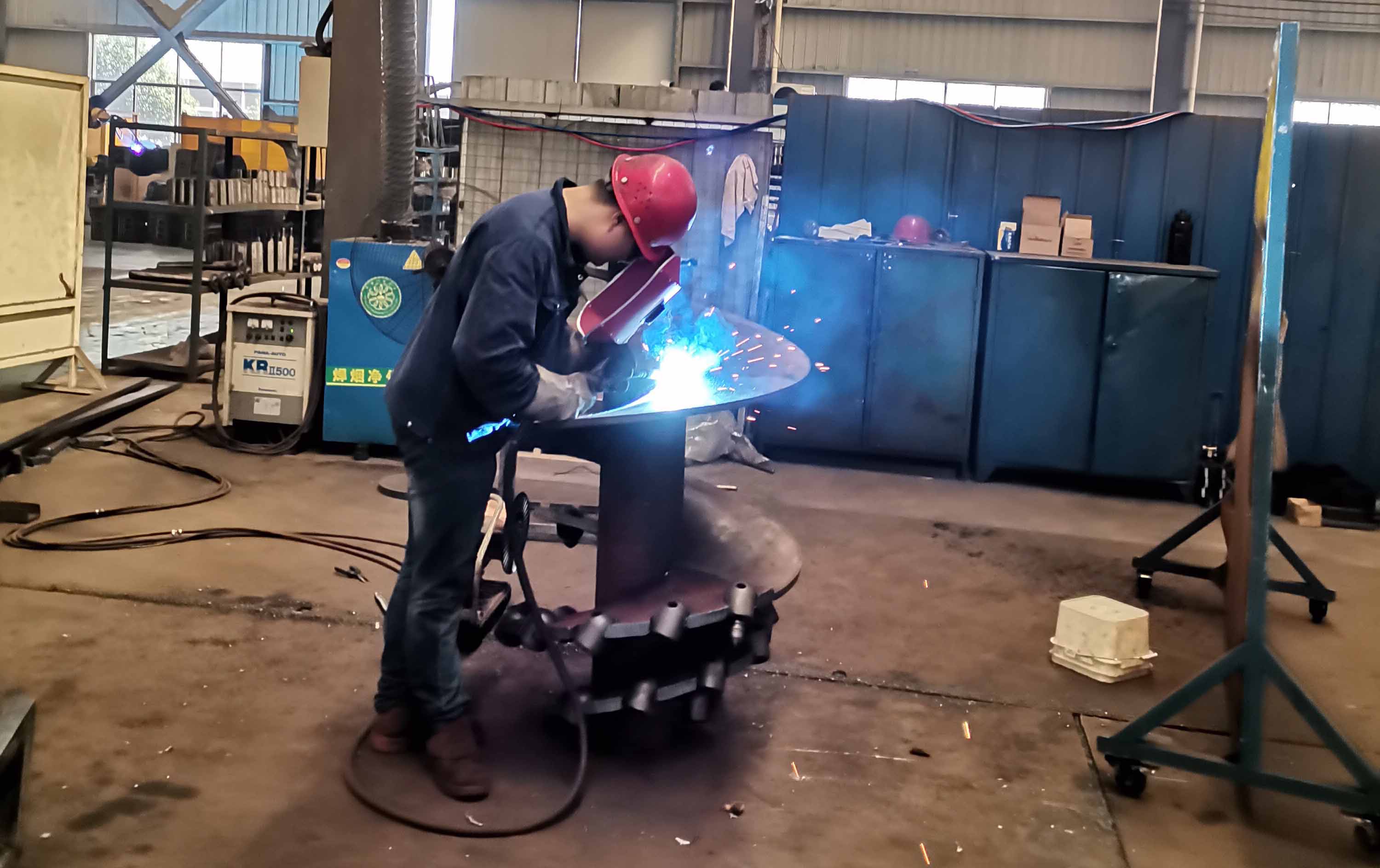

1. Using raw materials from a top-leading raw steel factory ensures the exceptional structural strength of our core barrel.

2. The use of 42CrMo tungsten carbide as the raw material for the cones suggests high durability and wear resistance, which are crucial for drilling through tough materials like those with compressive strengths ranging from 80 to 160 MPa.

3. We integrate hard-facing strips into our drilling buckets for superior wear protection, ensuring high wear resistance in demanding conditions.

4. A specialized design feature of the drilling teeth. This design may enhance the efficiency and effectiveness of the drilling process by optimizing the angle of the drilling teeth.

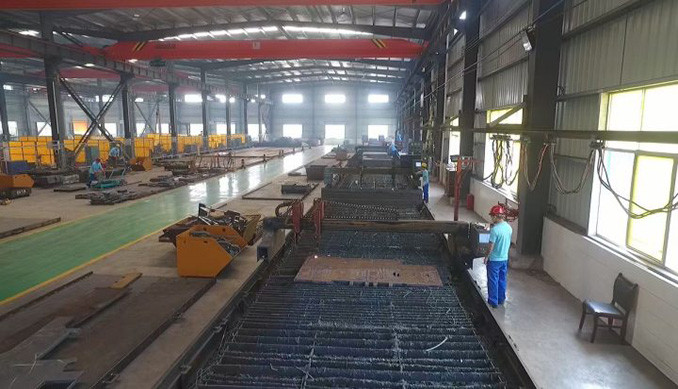

5. With a modern workshop, advanced production equipment, and automated robot welding technology, we guarantee a higher quality standard for our drilling tools, ensuring precision and reliability in every product.

Specification:

Pile Diameter (mm) | Shell Height (mm) | Shell Thickness (mm) | Stiffening Ring Thickness (mm) | Stiffening Ring Height (mm) | Teeth Quantity ( Piece ) | Weight (KG) |

⌀ 600 | 1200 | 20 | 40 | 250 | 4 | 650 |

⌀ 800 | 1200 | 20 | 40 | 250 | 6 | 850 |

⌀ 900 | 1200 | 20 | 40 | 250 | 8 | 1000 |

⌀ 1000 | 1200 | 20 | 40 | 250 | 8 | 1100 |

⌀ 1200 | 1200 | 20 | 40 | 250 | 10 | 1350 |

⌀ 1500 | 1200 | 20 | 40 | 250 | 12 | 1700 |

⌀ 1600 | 1200 | 20 | 40 | 250 | 14 | 1900 |

⌀ 1800 | 1000 | 20 | 40 | 250 | 16 | 2000 |

⌀ 2000 | 800 | 20 | 40 | 250 | 18 | 1900 |

⌀ 2200 | 800 | 20 | 40 | 250 | 20 | 2160 |

⌀ 2500 | 800 | 25 | 40 | 250 | 20 | 2350 |

⌀ 2800 | 800 | 25 | 40 | 250 | 24 | 3050 |

⌀ 3000 | 800 | 30 | 40 | 250 | 26 | 4250 |

Product Details:

Production Line:

Workshop:

Packing and Delivery: