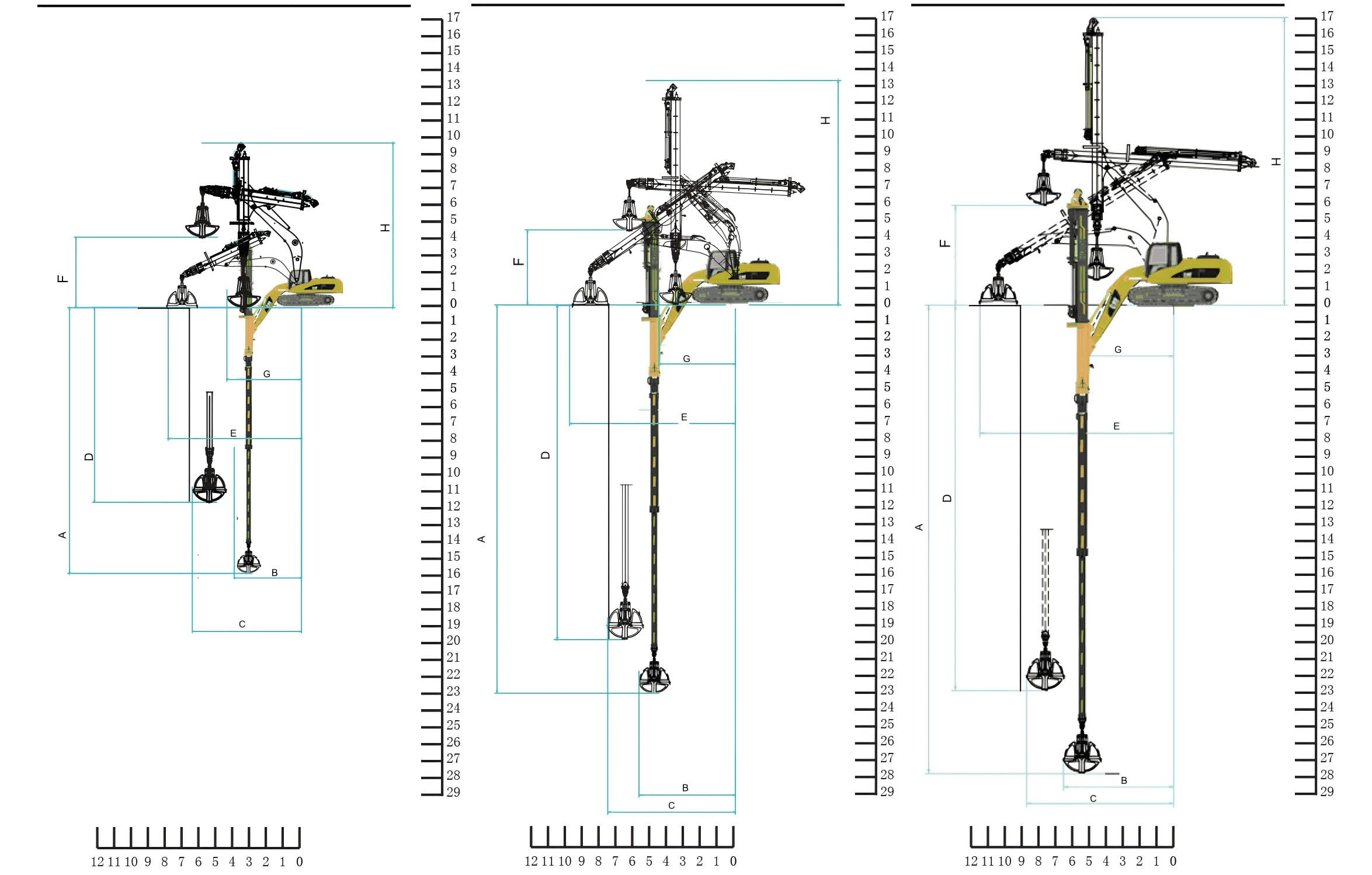

KM220 Clamshell telescopic arm

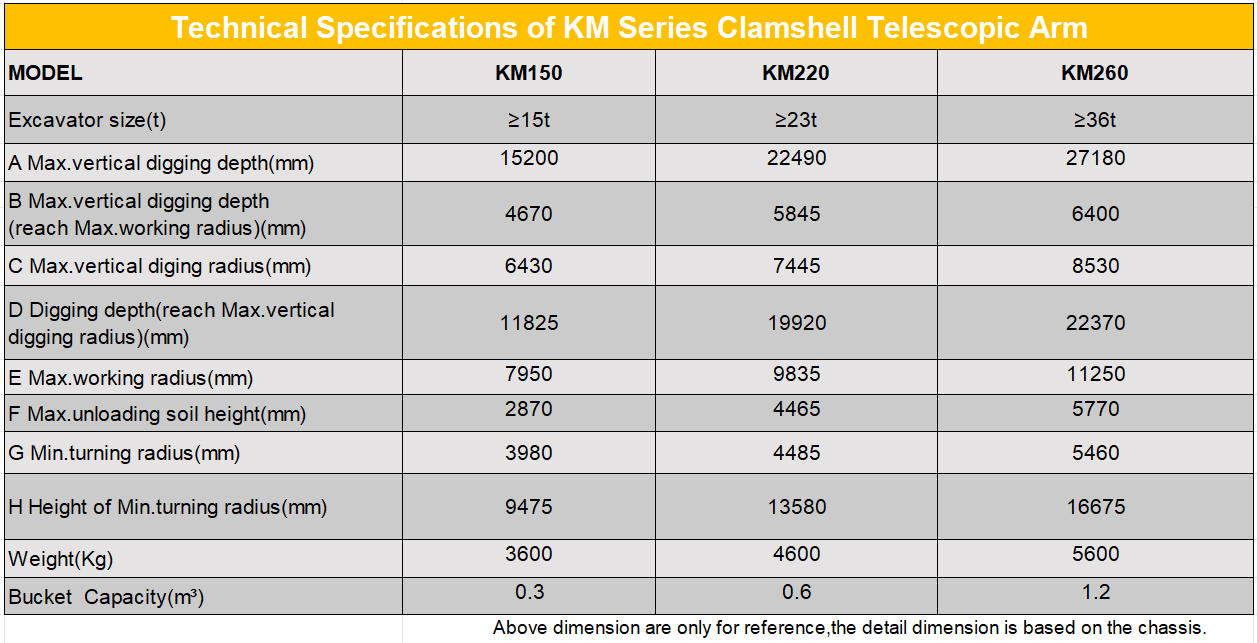

Specification:

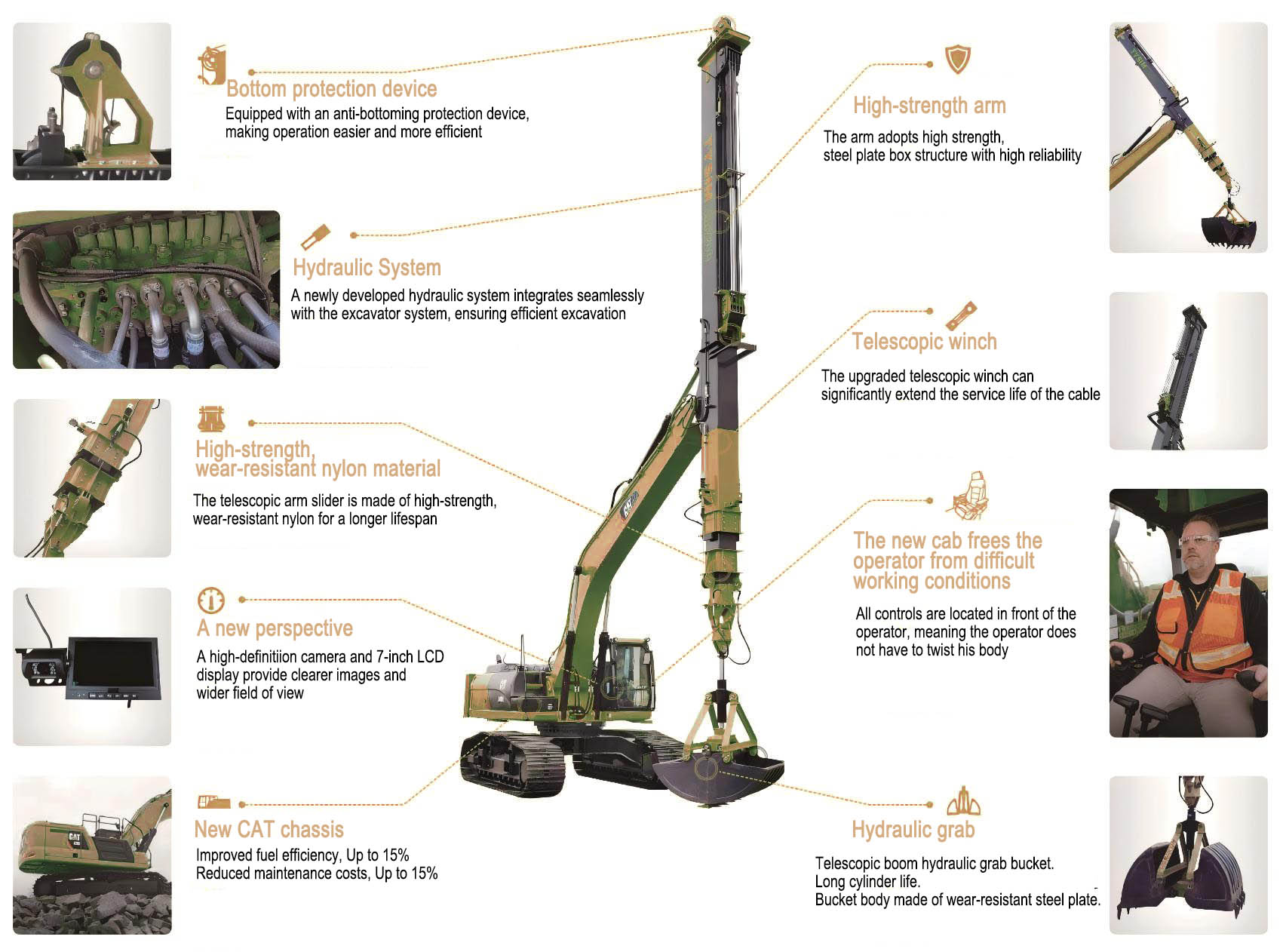

Feature:

Advantages:

A unique hose adjustment device and auxiliary monitoring device effectively prevent secondary quality failures caused by natural deformation during use, while also making maintenance during construction easier.

A high-definition camera transmits signals back to the cab display, making observation more convenient and improving safety during construction.

The use of anti-torsion steel wire ropes, combined with steel pulleys highly matched to the ropes, reduces rope wear and extends service life, achieving 2,000 hours of trouble-free operation.

All shafts are made of alloy steel, and their manufacturing is included in special process control. With strict process flow and heat-preservation facilities, the strength of the shafts is ensured.

Centralized lubrication (using stainless steel pipes) provides convenience and safety for equipment maintenance.

The nylon plates are made of high-quality nylon material, featuring excellent impact resistance, fatigue resistance, and acid-alkali resistance, along with strong load-bearing capacity and outstanding wear resistance, which extend their service life.

The guide rail adopts an integrated design. To ensure precision, it is machined using a gantry machining center, guaranteeing smooth operation between the sliding frame and the guide rail, thus ensuring the stability of the telescopic arm during construction.

Case: