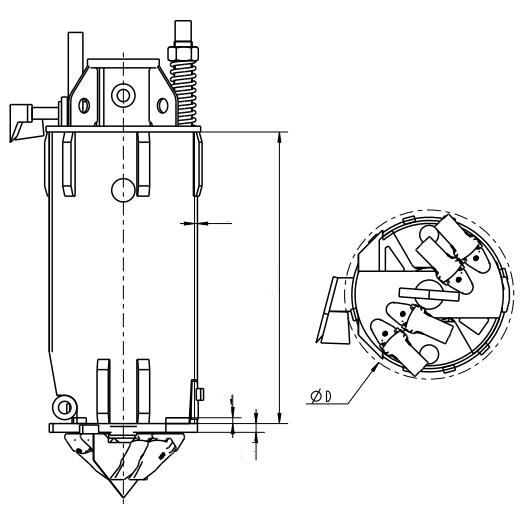

Soil Bucket with Soil teeth

Feature:

1. Large-scale Cutting: The soil bucket with double-bottom sand scooping adopts a special "double-bottom scooping" structure during cutting, which can increase the contact area of the soil teeth with the soil layer, significantly improving cutting efficiency and stability.

2. Adapting to Different Geological Conditions: The structure of the soil drilling bucket with double-bottom sand scooping is flexible, allowing adjustment of the drill bit parameters according to different geological conditions, thus enhancing drilling efficiency and success rate.

3.Wear-resistant and Durable: The square-tooth drill bit with double-bottom sand scooping is made of wear-resistant high-strength materials, possessing excellent wear resistance and toughness, resulting in a long service life.

4. High Drilling Efficiency: The soil bucket with double-bottom sand scooping utilizes efficient cutting structures and hydraulic balance technology, enabling efficient drilling even in complex geological conditions, thereby shortening the drilling cycle.

5. Custom Tooth Designs: We offer customization options to assemble various tooth types such as V20 teeth, FZ80 teeth, FZ72 teeth, 22S teeth, TL18 teeth, TL25 teeth, according to customer requirements.

6. Suit with silt, grave, clay and highly weathered soft geology condition.

Advantages:

1. True factory, with robust production capacity, offering competitive factory prices and ensuring timely delivery.

2. OEM options are available, supported by a professional R&D team.

3. Double support plate unlocking design, enhanced protection block, and disconnect contact unlocking mechanism are exclusive patented designs of our factory, aimed at enhancing performance and safety.

4. We use top-quality raw materials, including high-grade international standard steel plates, ensuring the highest level of quality in our products.

5. We incorporate a double cambered positioning cutting surface, drawing on our professional experience to optimize the angle of drilling teeth for enhanced performance.

Specification:

Pile Diameter (mm) | Shell Height (mm) | Shell Thickness (mm) | Fixed Bottom Thickness (mm) | Rotate Bottom Thickness (mm) | Teeth Quantity ( Piece ) | Weight (KG) |

⌀ 600 | 1200 | 16 | 40 | 40 | 4 | 650 |

⌀ 800 | 1200 | 16 | 40 | 50 | 4 | 900 |

⌀ 900 | 1200 | 16 | 40 | 50 | 5 | 1050 |

⌀ 1000 | 1200 | 16 | 40 | 50 | 5 | 1200 |

⌀ 1200 | 1200 | 16 | 40 | 50 | 7 | 1500 |

⌀ 1500 | 1200 | 16 | 40 | 50 | 9 | 2100 |

⌀ 1600 | 1200 | 16 | 40 | 50 | 9 | 2350 |

⌀ 1800 | 1000 | 20 | 50 | 50 | 10 | 3100 |

⌀ 2000 | 800 | 20 | 50 | 50 | 14 | 3550 |

⌀ 2200 | 800 | 20 | 50 | 50 | 16 | 4100 |

⌀ 2500 | 800 | 25 | 50 | 50 | 19 | 5500 |

⌀ 2800 | 800 | 25 | 50 | 50 | 22 | 6300 |

⌀ 3000 | 800 | 25 | 50 | 50 | 24 | 7800 |

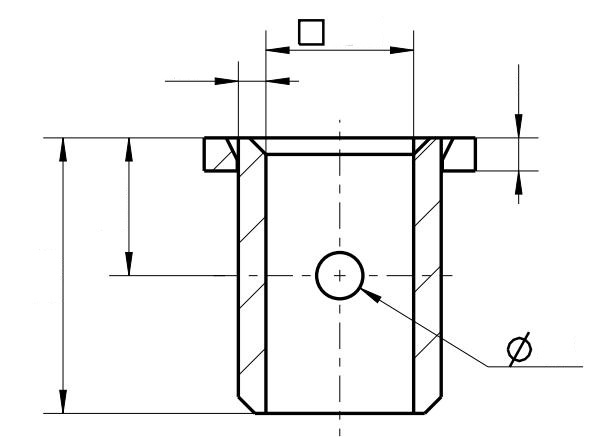

Product Details:

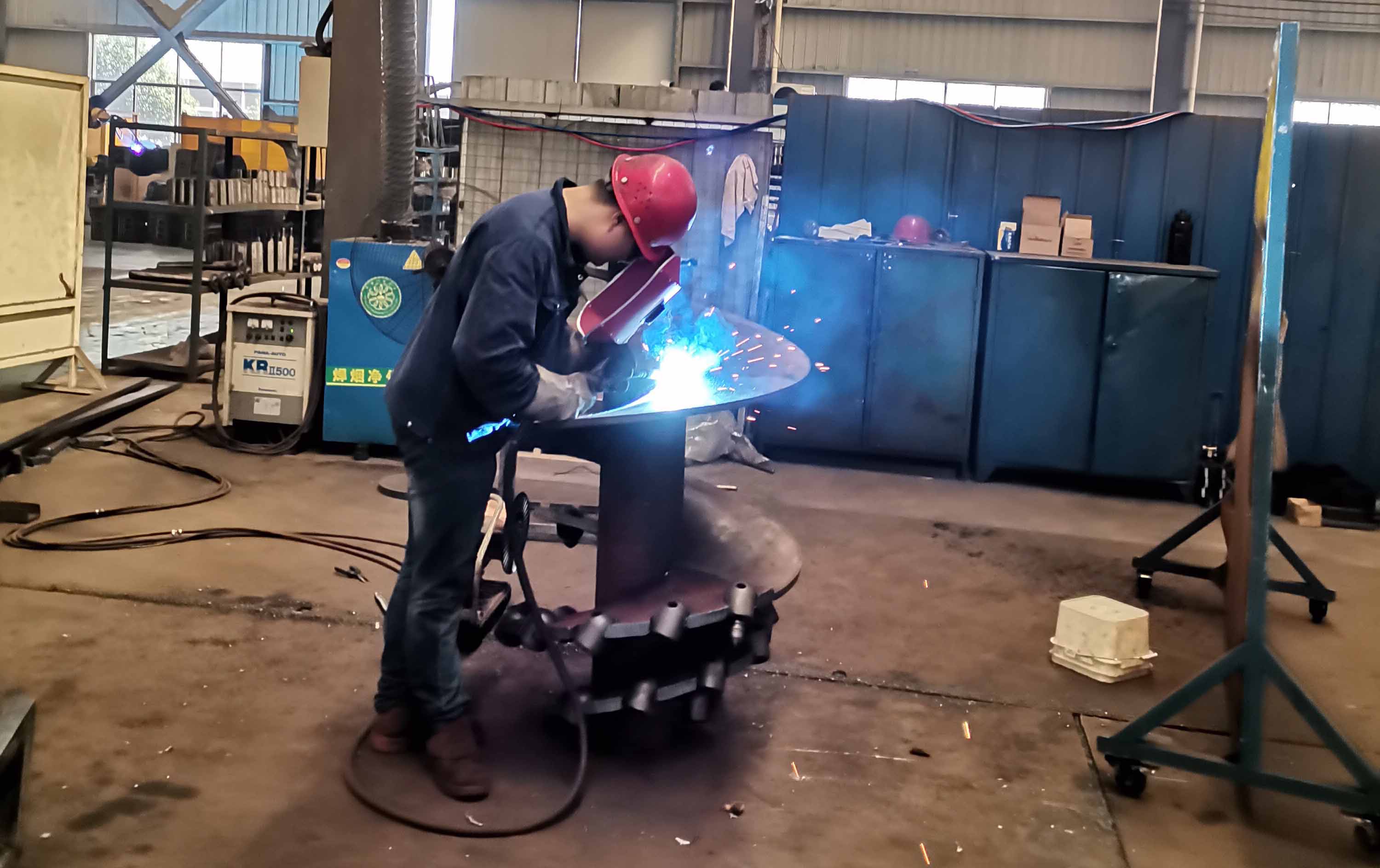

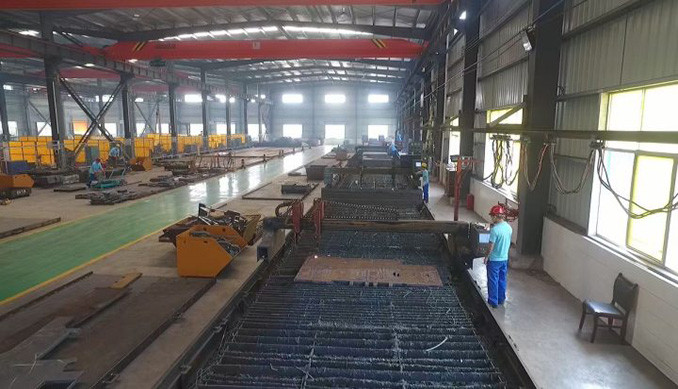

Production Line:

Workshop:

Packing and Delivery: