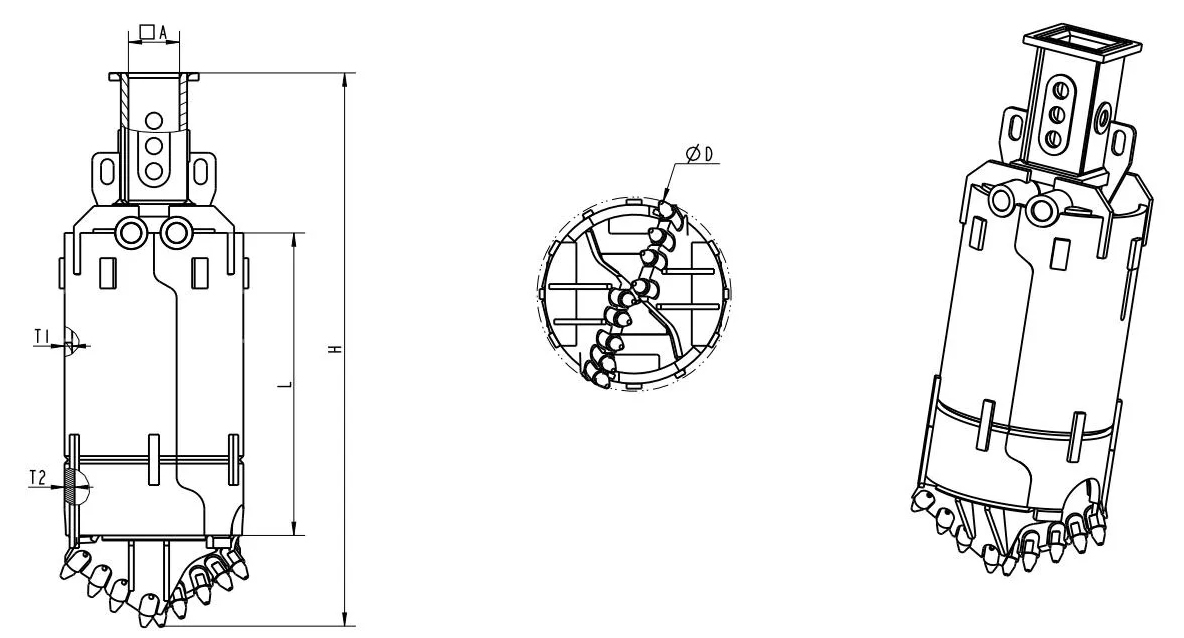

Open type bucket with rock teeth

Feature:

1. Large Inlet of Soil: This suggests a design with a wide opening or inlet for the soil to enter the drilling mechanism easily. This would allow for faster excavation and a higher volume of material processed.

2. Open Shell Design: An open shell design implies that the drilling apparatus has a structure that is not fully enclosed or sealed. This openness could facilitate the dumping of spoil (excavated material) without the need for complicated mechanisms to open and close compartments.

3. Easy to Dump Spoil: The ability to easily dump spoil suggests a feature such as a tilting or dumping mechanism that allows the excavated material to be released from the drilling equipment without significant effort or time. This feature is crucial for maintaining efficiency during drilling operations, as it minimizes downtime for spoil removal.

4. Suit with the clay, silt, hiighly weathered rock.

Advantages:

1. Using raw materials from a top-leading raw steel factory ensures the exceptional structural strength of our open type bucket.

2. Our drilling bucket offers a simple operation, making it much easier for the operator to accomplish the bored hole drilling job efficiently.

3. We integrate hard-facing strips into our drilling buckets for superior wear protection, ensuring high wear resistance in demanding conditions.

4. The excellent roundness of the cylinder, optimized angle of drilling bits, and strategically placed ventilation holes contribute to higher drilling efficiency in our drilling buckets.

5. Incorporating double support plate unlocking design and enhanced protection block design, among other patented innovations, our drilling buckets offer advanced features for enhanced performance and durability.

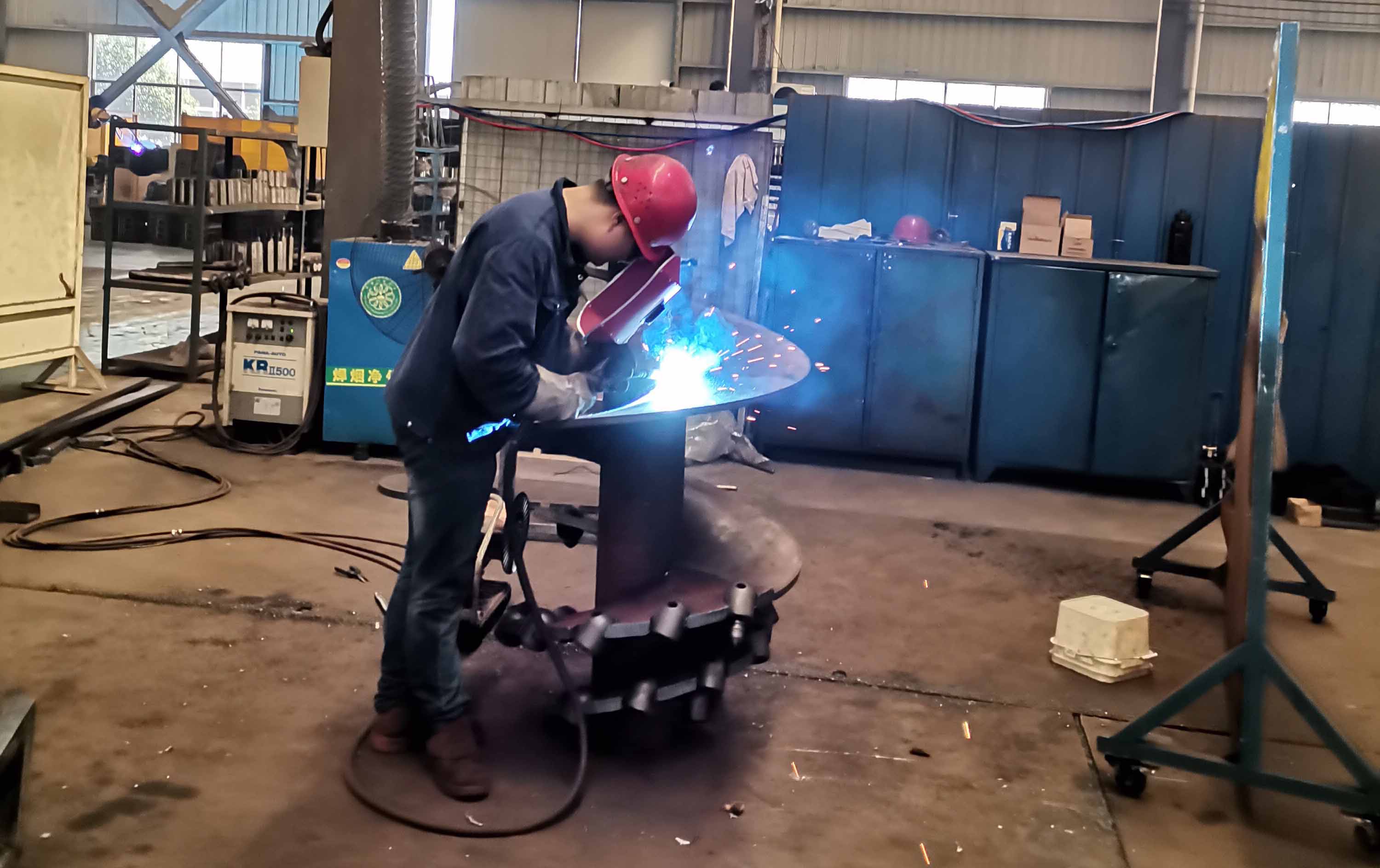

6. With a modern workshop, advanced production equipment, and automated robot welding technology, we guarantee a higher quality standard for our drilling tools, ensuring precision and reliability in every product.

Specification:

Pile Diameter (mm) | Shell Height (mm) | Shell Thickness (mm) | Stiffening Ring Thickness (mm) | Stiffening Ring Height (mm) | Teeth Quantity ( Piece ) | Weight (KG) |

⌀ 600 | 1200 | 25 | 40 | 300 | 7 | 800 |

⌀ 800 | 1200 | 30 | 40 | 300 | 9 | 1350 |

⌀ 900 | 1200 | 30 | 40 | 300 | 10 | 1550 |

⌀ 1000 | 1200 | 30 | 40 | 300 | 12 | 1900 |

| ⌀ 1200 | 1200 | 30 | 40 | 300 | 13 | 2250 |

Product Details:

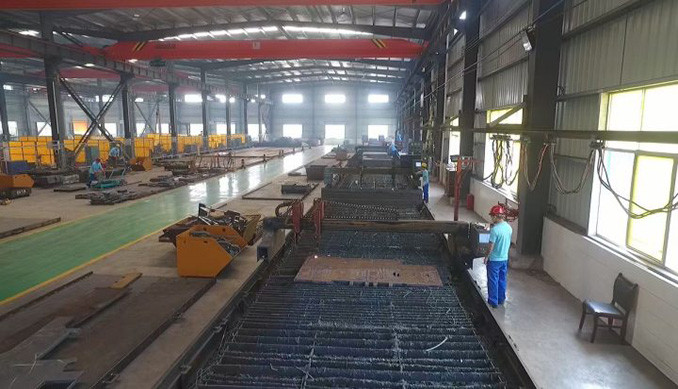

Production Line:

Workshop:

Packing and Delivery: